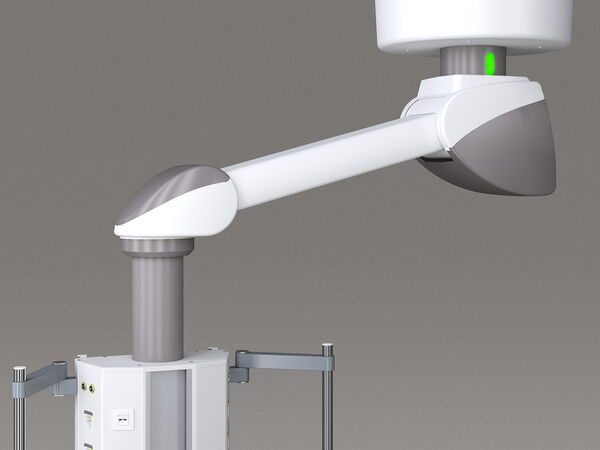

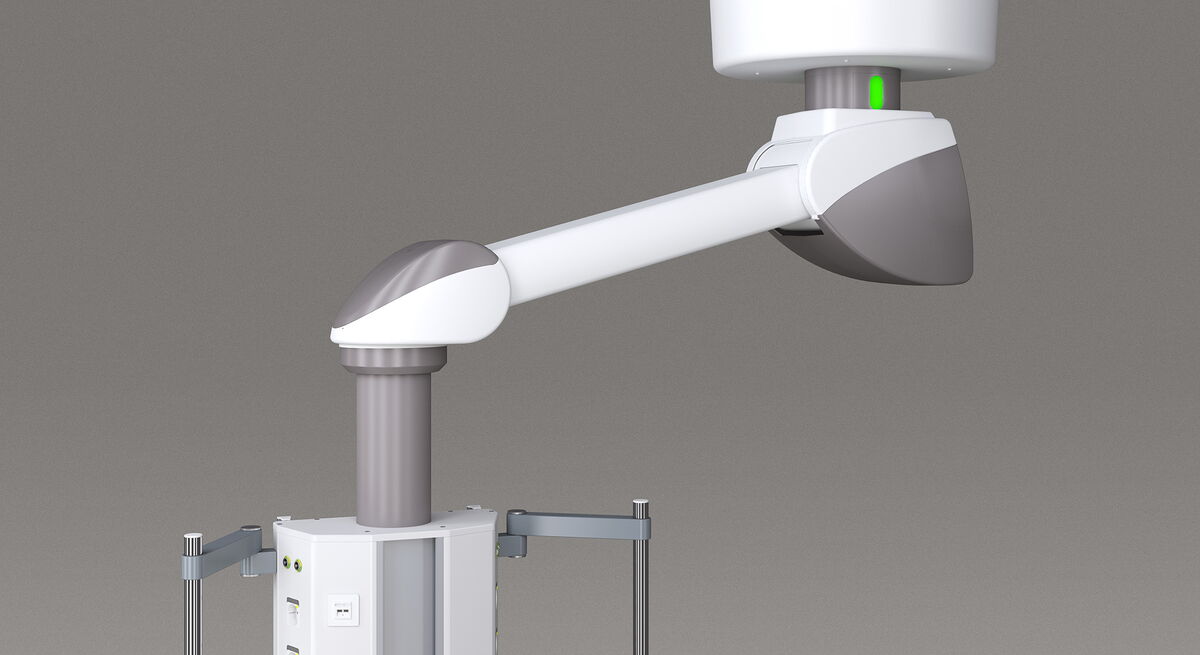

Gentle positioning without jerks!

The highlight of moduversa HM is the sophisticated bearing system of the joints and particularly in the motor which drives the articulated joint for the vertical positioning.

Through the soft-start drive technology the system starts up extremely gently and moves BSP 2500 supply head including all the monitors and apparatus attached to it into the desired position without any start-up jerking. No wobbling, no dropping of attached items - only gentle gliding into the desired position.

The electromagnetic braking system has LED lights at each joint which makes correct operation considerably easier. The integrated dimmable LED lighting in the horizontal arm improves illumination of the work area.

The maximum arm load capacity of 150 kg is sufficient for most medical applications.

And by the way, all products in the moduversa range have been designed so they also retain their respective position in the event of power failures and can even be positioned by hand.

moduversa HM can be designed as a single or tandem system.

Key Details

Electric specifications

Nominal voltage: 115 V - 240 V / 50-60 Hz - continuous operation

Protection class: I

Protection type: IP 20

Operating pressure of medical gas technology

Oxygen: 5 bar

Compressed air: 5 bar

Compressed air: 8 bar

Vacuum: - 0,8 bar

Laughing gas 5 bar

CO2: 5 bar

AGSS: 5 bar

Air-Motor: 8 bar

General information

Media current feed: From the top in the support arm

Braking system: Electromagnetic (optional compressed air)

Comfort option: Braking system with BrakeGuide *(optical feedback)

Total additional load of supply unit: Project-related

Height-adjustment: Electric motor

* BrakeGuide cannot be combined with compressed air brake

Support arm length

1000 mm

Max. additional load support arm

150 kg / 250 kg*

* Max. additional load with XL-bearing (optional)

HOT OFF THE PRESS, DIGITAL ONLY - OUR BROCHURES

moduversa – Gentle positioning without jerks!

Assembly, cleaning and maintenance

01. Assembly

The medical supply units and single-bed lighting fixtures can be installed and mounted on solid or plasterboard construction walls. Customer provided substructure is required for plasterboard walls.

02. Cleaning

Our products can be cleaned with conventional cleaning agents and disinfected with alcohol-free disinfectants.

Surfaces are protected by high-quality electrostatic powder coating. Non-coated parts are made of anodized aluminium or chrome-nickel steel. All plastic parts are resistant to cleaning agents and disinfectants.

03. Maintenance & repair

The medical supply units are virtually maintenance-free. Wearing parts such as plastic covers or sockets can be reordered and easily replaced. Further information can be found in the operating instruction.

04. Accessories

Our comprehensive range of accessories means you can set up your work area exactly as you want it. Consult our Accessories Catalogue to find out about the wide range of options available to you.

Your contact

Hendrik Balagny

Sales Director

Tel.: +49(0)2602/9449-31

Fax: +49(0)2602/9449-11

Mob: +49(0)176/10089108

E-Mail: hbalagny@modul-technik.de

„Good solutions start with listening. The direct connection to the customer is the key for me.“